About | Awards & Accomplishments

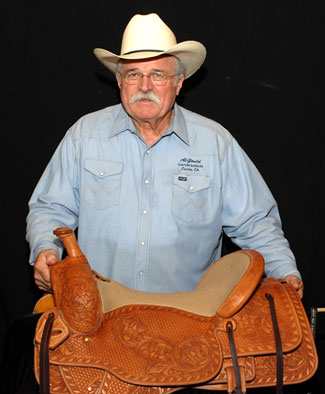

Al’S Bio

Al’s career as a custom saddle maker began when his grandmother gave him as set of leather working tools when he was 9-years old. By the time he was in junior high, his ability to stamp came to the attention of Slim Beaver who owned a saddle shop right across the street from the Clovis Rodeo Grounds, home to one of the largest spring rodeos in California.

Al’s career as a custom saddle maker began when his grandmother gave him as set of leather working tools when he was 9-years old. By the time he was in junior high, his ability to stamp came to the attention of Slim Beaver who owned a saddle shop right across the street from the Clovis Rodeo Grounds, home to one of the largest spring rodeos in California.

Before long, Al was stamping saddles and other leather items after school. At the time, another saddle maker, CH Mavis, was also working for Beaver. However, due to advanced arthritis in both hands, Mavis’ work was reduced to cutting leather and building saddles as he didn’t have the dexterity required to stamp the intricate patterns popular with the saddle shops customers.

“Mavis was getting up there in years,” Gould recalls, “once he discovered that I could stamp, he’d cut the leather during the day and put the damp pieces in a plastic bag until I got there after school. Looking back, that experience taught me early on that there had to be a logical process in the production of a saddle, you had to have a plan if you were going to be efficient and produce a quality product at an affordable price.”

By the time Al entered college, his interest in football and steer wrestling, took his attention away from the saddle shop. However, when Mavis quit working for Slim Beaver, Al was asked to help fill the orders that had stacked up. Al soon found himself building saddles, not only stamping leather.

In the late 60s, cutting was becoming more popular in California, thanks to trainers like Don Dodge and horses like Doc Bar, a stallion that was revolutionizing the sport through his progeny. With this trend, came the need for a saddle with a different seat, however, very few saddle makers could satisfy the demand.

At the time Al was getting started, Art Vancore, who had a shop in Merced, was the saddle maker of choice. He had been making saddles for top horsemen for years. Vancore had a long waiting list and some of his customers were less than patient. He became aware of the saddles that Al had been building and was impressed; not only with his craftsmanship, but also with the care Al gave to saddle building. When he couldn’t meet a customer’s deadline, he referred them to Al. With his endorsement, Al’s reputation as a custom saddle maker and his list of customers grew.

In the 1970s, Al was hired by the McPherson Leather Company in Los Angeles to help design saddles to meet the emerging West Coast market. His talents in this area soon attracted the attention of Resistol, the legendary hat company that was expanding into the Western apparel business. Resistol was looking for someone who understood horse culture, especially rodeo. Al was hired and moved to New Mexico and then Texas.

In the early 1990s, Al decided to give up the corporate life and returned to Clovis where he dedicated himself to saddle making full time. He continued to work to improve his saddle making and leather working skills, building a clientele that included the region’s top horsemen.

He also began teaching at Leather Shows and passed through Nevada a number of times on his way to Sheridan, Wyoming. Al and Diana fell in love with the Carson Valley and the little town of Minden. “There’s more cows and horses here than you can count” he notes and the peaceful setting with wide open spaces was exactly what he and Diana wanted for their dream locale. “It’s perfect, except I’m really missin’ my leather partner, Frank Toste,”, Al’s sidekick in the shop for over 25 years.

Al’s goal is always to craft a saddle that is fully functional and perfectly suited to the person who will ride it. He never duplicates a saddle. They all have the same function but each one is unique, "Each saddle is custom, each saddle is built for a particular person."

Al’s Signature Swivel Knife Cuts

C.H. Mavis was Al’s mentor in the saddle business in the 60’s. Mavis once showed Al a belt that had only swivel knife cuts. It had been made for him by an Indian leather stamper who worked with him at Porter Saddle Company of Arizona. The belt was the most magnificent piece of swivel knife artwork Al had ever seen. Al said "I had never seen anything like that in leather. If you looked carefully, you could see birds were integrated in the design, yet it just flowed all together. The belt made me realize that you could use the swivel knife to cut in a pattern, or you could use it to make a stand-alone piece of art."

C.H. Mavis was Al’s mentor in the saddle business in the 60’s. Mavis once showed Al a belt that had only swivel knife cuts. It had been made for him by an Indian leather stamper who worked with him at Porter Saddle Company of Arizona. The belt was the most magnificent piece of swivel knife artwork Al had ever seen. Al said "I had never seen anything like that in leather. If you looked carefully, you could see birds were integrated in the design, yet it just flowed all together. The belt made me realize that you could use the swivel knife to cut in a pattern, or you could use it to make a stand-alone piece of art."

The saddles Al now makes are adorned with swivel knife cuts on the fork, cantle and latigo carriers. This adornment had become the signature of his work.

The proper use of the swivel knife is one of the skills that Al teaches at the Leather Trade Shows. Al believes that it is by teaching that he can pass on what has been given to him. Al hopes that he can inspire others as he was once inspired.

“I've been riding Al Gould saddle since he has been making them. They are the absolute best, by far. He is such a master with the ground seat that they fit, period. People talk about a saddle having a 'pocket' They don't need a pocket if the ground seat is done correctly. His artistic ability is outstanding and each saddle is distinctive. Both of us have ridden his saddles to the winners circle many times. Whether you ride one for show or for pleasure, you can be in one all day and be comfortable the whole time.”

- Kathy Gould, Saddle –Up Enterprises